Harrisville Designs Loom FAQ

Harrisville Designs looms are my favorites to weave on and because of this I get a lot of questions from people who buy used ones that are in need of maintenance or restoration. I'm here to help. Some of the information may also be applied to the operation of other looms so check it out. If you have any additional questions, feel free to contact me or write/call Harrisville Designs. Their customer service is very good.

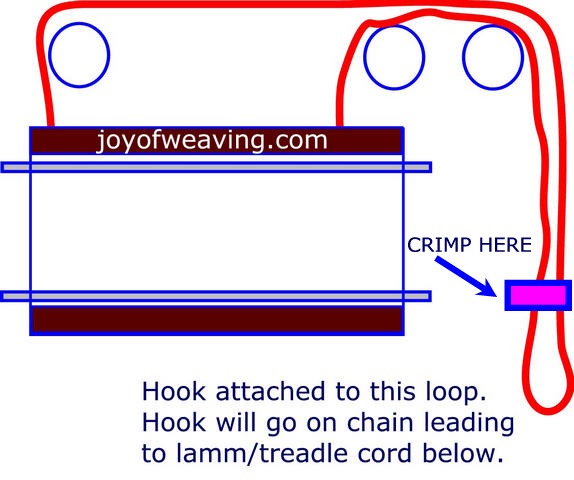

SHAFT PULLEY CORDS

This is how the shaft pulley cord goes on the Harrisville Designs Loom. Do this for each shaft.

If you need to replace them you may order new cords from Harrisville Designs or make your own out of any sturdy, flexible material that won't stretch or break. I can't say enough about using Texsolv for this application because it eliminates the loop with crimps on the ends to attach to the shafts, but if you can't get any, you may use things like an old indoor electrical extension cord split in half, speaker wire, venetian blind cord, clothes line, high test plastic coated fishing line, etc.

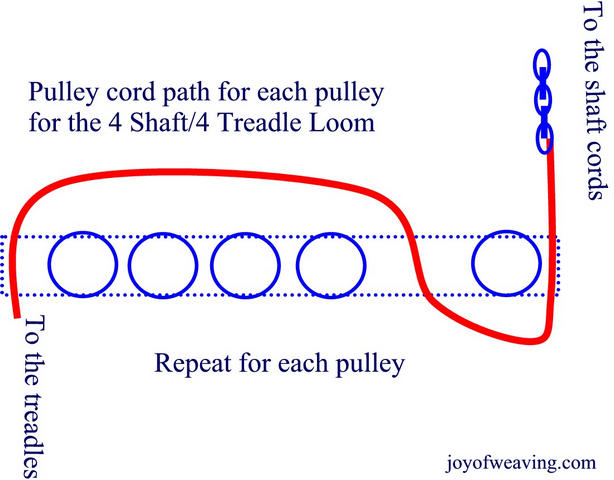

TREADLE CORDS FOR 4 SHAFT / 4 TREADLE LOOMS

This is the path for the cords that go to the 4 shaft, 4 treadle loom that doesn't have any lamms. This is known as "direct tie-up" as each shaft has its own treadle. While you're at this, you may consider configuring them in the 1-3-2-4 configuaration suggested by Peggy Osterkamp. I can't say enough good things about it. More about that HERE.

There is a chain that goes between the treadle cords and the shaft cords. This is so that you may adjust the height of the shafts without having to get on the floor to monkey with the rope at the treadle level (where this is normally done).

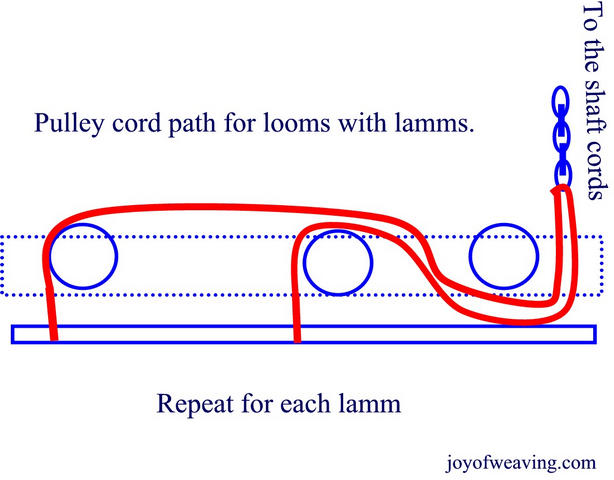

TREADLE CORDS FOR LOOMS WITH LAMMS

The configuration for the treadle cords going to lamms is just like the ones going to the shafts except rather than going downward at the side of the castle, the cords go upwards to meet the cords coming down from the shafts.

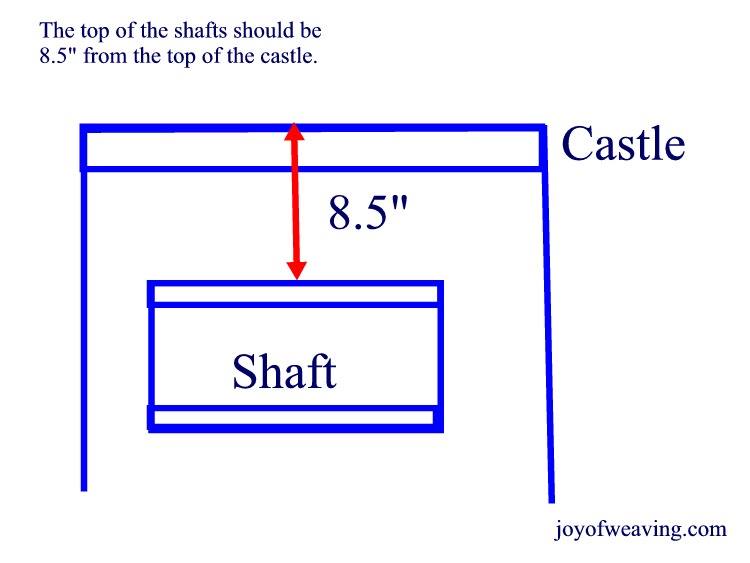

HEIGHT OF THE SHAFTS

The correct height for the shafts is when the top of the shaft is 8 to 8 1/2" from the top of the castle.

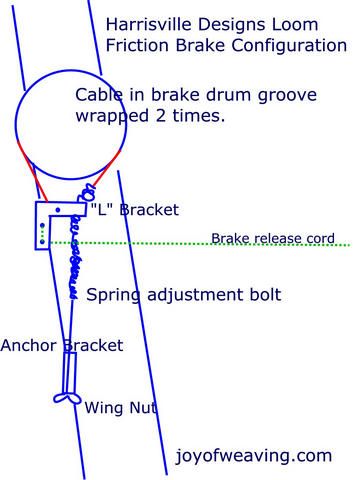

FRICTION BRAKE

This is how the hardware for the friction brake should be configured.

If your break is missing or broken, this is a quick fix. More about this can be found HERE.

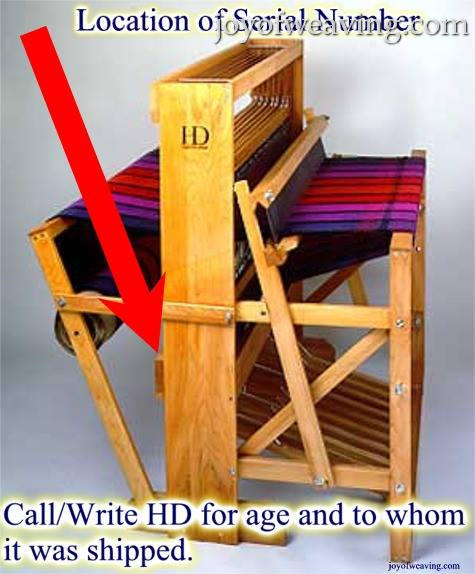

SERIAL NUMBER

The serial number is stamped on this board on your loom. If you call or write Harrisville Designs, they will be able to tell you when your used loom was manufactured.

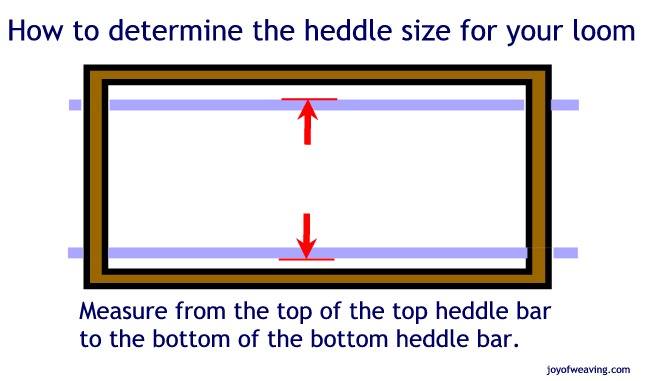

SIZE OF HEDDLES USED

To determine the size of heddles to use for this or any loom, simply measure the distance between the top of the top heddle bar to the bottom of the bottom heddle bar. Harrisville Designs Looms require 10 1/2" heddles.

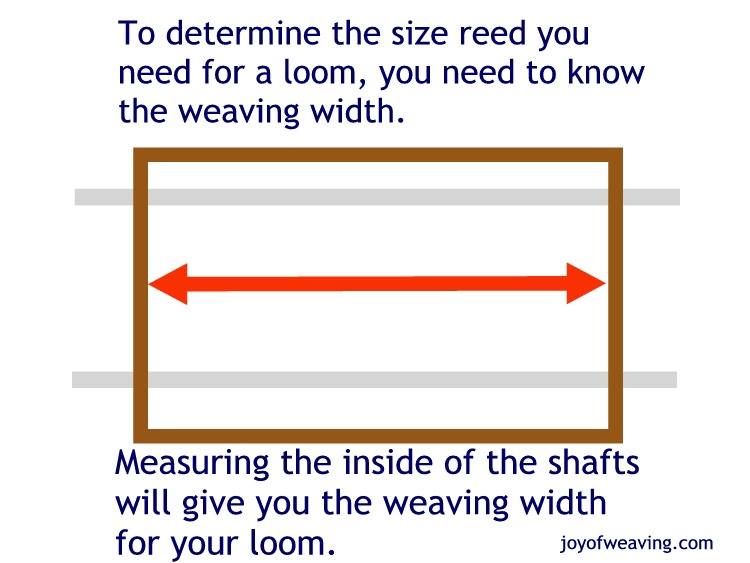

SIZE OF REED USED

To determine the size of a reed to use with this or any loom, you need to know the weaving width of the loom. To find this, simply measure the distance between the inside opening of the loom's shafts. This is the widest you may weave with your loom. This is your "weaving width". Most looms are defined by this measurement. Harrisville Designs' Looms are defined by this measurement e.g. their 22" loom has a 22" weaving width.